Also hier mal die config.default.ini.

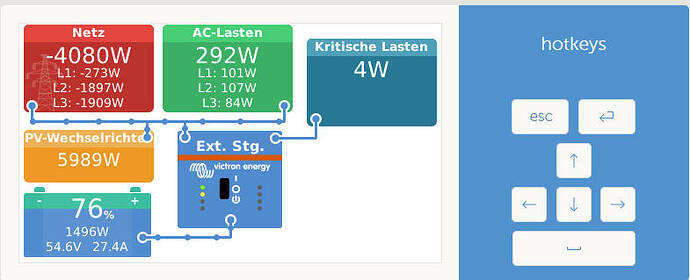

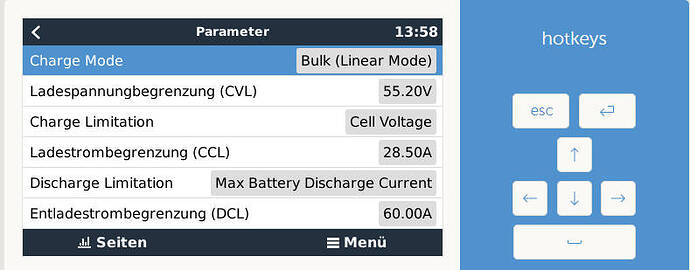

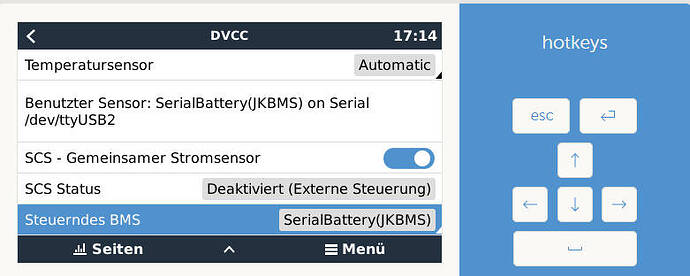

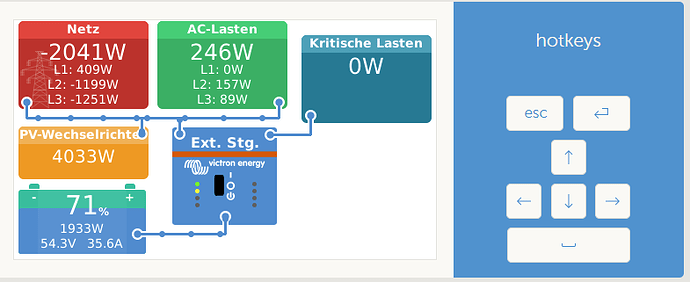

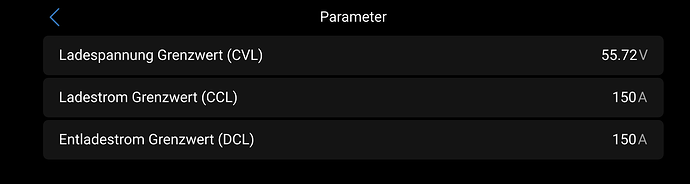

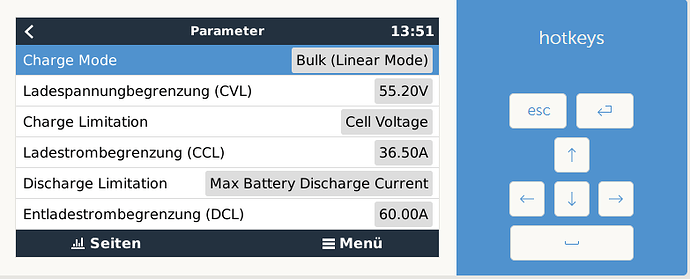

Momentan ist der Akku bei 71% 54,3V und er läd leider nur mit 36,4A(maximal 50A) und es wird ins 1382W ins Netz gedrückt. Normalerweise sollte er doch mit einem größeren Strom laden.

[DEFAULT]

; --------- Set logging level ---------

; ERROR: Only errors are logged

; WARNING: Errors and warnings are logged

; INFO: Errors, warnings and info messages are logged

; DEBUG: Errors, warnings, info and debug messages are logged

LOGGING = INFO

; --------- Battery Current limits ---------

MAX_BATTERY_CHARGE_CURRENT = 60.0

MAX_BATTERY_DISCHARGE_CURRENT = 60.0

; --------- Cell Voltages ---------

; Description:

; Cell min/max voltages which are used for:

; - Calculating the min/max battery voltage

; - Trigger the SoC reset when SoC calculation is enabled

; Example:

; 16 cells * 3.45 V/cell = 55.2 V max charge voltage.

; 16 cells * 2.90 V/cell = 46.4 V min discharge voltage

MIN_CELL_VOLTAGE = 2.900

; Max voltage (can seen as absorption voltage)

MAX_CELL_VOLTAGE = 3.450

; Float voltage (can be seen as resting voltage)

FLOAT_CELL_VOLTAGE = 3.375

; --------- SOC reset voltage (needs to match BMS settings) ---------

; +++ This has nothing to do with "SOC calculation" in a section below +++

; This is one of the possibilities to reset the SoC to 100%, because of SoC drift.

; Description:

; May be needed to reset the SoC to 100% once in a while for some BMS, because of SoC drift.

; Some BMS may needed to reset the SoC to 100% once in a while, because of SoC drift. Some

; devices, like JKBMS, will reset their internal SOC value, if they reach the upper voltage level.

; Using this method, the charging voltage can be raised regularly to achieve that.

; (other BMS like Daly need an active overwriting of the SOC parameter. This happens each time when

; the charging mode changes from Bulk/Absorption to float (and the cells are equalised). They do

; not need this feature here.)

; Specify the cell voltage where the SoC should be reset to 100% by the BMS.

; - JKBMS: SoC is reset to 100% if one cell reaches OVP (over voltage protection) voltage

; As you have to adopt this value to your system, I recommend to start with

; OVP voltage - 0.030 (see Example).

; - Try to increase (add) by 0.005 in steps, if the system does not switch to float mode, even if

; the target voltage SOC_RESET_VOLTAGE * CELL_COUNT is reached.

; - Try to decrease (lower) by 0.005 in steps, if the system hits the OVP too fast, before all

; cells could be balanced and the system goes into protection mode multiple times.

; Example:

; If OVP is 3.650, then start with 3.620 and increase/decrease by 0.005

; Note:

; The value has to be higher as the MAX_CELL_VOLTAGE

; You also have to set CELL_VOLTAGES_WHILE_CHARGING accordingly, if you set CCCM_CV_ENABLE to true

; else the charging current will be reduced to 0 before the target voltage is reached and the

; battery will never switch to float

SOC_RESET_VOLTAGE = 3.650

; Specify after how many days the SOC reset voltage should be reached again

; The timer is reset when the SOC reset voltage is reached

; Leave empty if you don't want to use the SOC reset feature

; Example:

; Value is set to 15

; day 1: SOC reset reached once

; day 16: SOC reset reached twice

; day 31: SOC reset not reached since it's very cloudy

; day 34: SOC reset reached since the sun came out

; day 49: SOC reset reached again, since last time it took 3 days to reach SOC reset voltage

SOC_RESET_AFTER_DAYS =

; --------- SOC calculation ---------

; +++ This has nothing to do with "SOC reset voltage" in a section above +++

; This is one of the possibilities to reset the SoC to 100%, because of SoC drift.

; Description:

; Calculate the SOC in the driver. Do not use the SOC reported by the BMS

; SOC_CALCULATION:

; True: Calc SOC in the driver, do not use SOC reported from BMS

; - The SOC is calculated by integration of the current reported

; - The current reported can be corrected by the map

; (SOC_CALC_CURRENT_REPORTED_BY_BMS, SOC_CALC_CURRENT_MEASURED_BY_USER)

; - The SOC is set to 100% if the following conditions apply for at least SOC_RESET_TIME seconds:

; * Highest cell voltage is higher or equal to MAX_CELL_VOLTAGE

; * Current is lower than SOC_RESET_CURRENT

; - The SOC is set to 0% if the following conditions apply for at least SOC_RESET_TIME seconds:

; * Lowest cell voltage is lower or equal to MIN_CELL_VOLTAGE

; * Battery is discharging

; - The calculated SOC is stored in dbus to persist a driver restart

; False: Use SOC reported from BMS (none of the other parameters apply)

; More info: https://github.com/Louisvdw/dbus-serialbattery/pull/868

SOC_CALCULATION = False

SOC_RESET_CURRENT = 7

SOC_RESET_TIME = 60

SOC_CALC_CURRENT_REPORTED_BY_BMS = -300, 300

SOC_CALC_CURRENT_MEASURED_BY_USER = -300, 300

; Example to set small currents to zero

; SOC_CALC_CURRENT_REPORTED_BY_BMS = -300, -0.5, 0.5, 300

; SOC_CALC_CURRENT_MEASURED_BY_USER = -300, 0, 0, 300

; --------- Bluetooth BMS ---------

; Description:

; Specify the Bluetooth BMS and it's MAC address that you want to install. Leave empty to disable

; Available Bluetooth BMS:

; Jkbms_Ble, LltJbd_Ble

; Example for one BMS:

; BLUETOOTH_BMS = Jkbms_Ble C8:47:8C:00:00:00

; Example for multiple BMS:

; BLUETOOTH_BMS = Jkbms_Ble C8:47:8C:00:00:00, Jkbms_Ble C8:47:8C:00:00:11, Jkbms_Ble C8:47:8C:00:00:22

BLUETOOTH_BMS =

; --------- Bluetooth use USB ---------

; Description:

; Some users reported issues to the built in bluetooth module, you can try to fix it with an USB

; module. After a change you have to run reinstall-local.sh and to manual reboot the device!

; The usb bluetooth module must have BLE support (bluetooth version >= 4.0)

; Other bluetooth devices such as Ruuvi tags not tested yet.

; False: Use the built in bluetooth module

; True: Disable built in bluetooth module and try to use USB module

BLUETOOTH_USE_USB = False

; --------- CAN BMS ---------

; Description:

; Specify the CAN port(s) where the BMS is connected to. Leave empty to disable

; Available CAN BMS:

; Daly_Can, Jkbms_Can

; Example for one CAN port:

; CAN_PORT = can0

; Example for multiple CAN ports:

; CAN_PORT = can0, can8, can9

CAN_PORT =

; --------- BMS disconnect behaviour ---------

; Description:

; Block charge and discharge when the communication to the BMS is lost. If you are removing the

; BMS on purpose, then you have to restart the driver/system to reset the block.

; False:

; Charge and discharge is not blocked on BMS communication loss for 20 minutes, if cell voltages are between

; 3.25 V and 3.35 V. Else the driver block charge and discharge after 60 seconds.

; True:

; Charge and discharge is blocked on BMS communication loss, it's unblocked when connection is established

; again or the driver/system is restarted. This is the Victron Energy default behaviour.

BLOCK_ON_DISCONNECT = False

; --------- Charge mode ---------

; Choose the mode for voltage / current limitations (True / False)

; False is a step mode: This is the default with limitations on hard boundary steps

; True is a linear mode:

; For CCL and DCL the values between the steps are calculated for smoother values

; For CVL max battery voltage is calculated dynamically in order that the max cell voltage is not exceeded

LINEAR_LIMITATION_ENABLE = True

; Specify in seconds how often the linear values should be recalculated

LINEAR_RECALCULATION_EVERY = 60

; Specify in percent when the linear values should be recalculated immediately

; Example:

; 10 for a immediate change, when the value changes by more than 10%

LINEAR_RECALCULATION_ON_PERC_CHANGE = 33

; --------- External current sensor ---------

; Specify the dbus device and path where the external current sensor is connected to

; You can find it by executing the dbus-spy command

; Example for a external current sensor connected to the VE.Bus port:

; EXTERNAL_CURRENT_SENSOR_DBUS_DEVICE = com.victronenergy.vebus.ttyS3

; EXTERNAL_CURRENT_SENSOR_DBUS_PATH = /Dc/0/Current

EXTERNAL_CURRENT_SENSOR_DBUS_DEVICE =

EXTERNAL_CURRENT_SENSOR_DBUS_PATH =

; --------- Charge Voltage limitation (affecting CVL) ---------

; Description:

; Limit max charging voltage (MAX_CELL_VOLTAGE * cell count), switch from max voltage to float

; voltage (FLOAT_CELL_VOLTAGE * cell count) and back

; False: Max charging voltage is always kept

; True: Max charging voltage is reduced based on charge mode

; Step mode: After max voltage is reached for MAX_VOLTAGE_TIME_SEC it switches to float voltage. After

; SoC is below SOC_LEVEL_TO_RESET_VOLTAGE_LIMIT it switches back to max voltage.

; Linear mode: After max voltage is reached and cell voltage difference is smaller or equal to

; CELL_VOLTAGE_DIFF_KEEP_MAX_VOLTAGE_UNTIL it switches to float voltage after MAX_VOLTAGE_TIME_SEC

; additional seconds.

; After cell voltage difference is greater or equal to CELL_VOLTAGE_DIFF_TO_RESET_VOLTAGE_LIMIT

; OR

; SoC is below SOC_LEVEL_TO_RESET_VOLTAGE_LIMIT

; it switches back to max voltage.

; Example when set to True:

; Step mode:

; The battery reached max voltage of 55.2 V and hold it for 900 seconds, the the CVL is switched to

; float voltage of 53.6 V to don't stress the batteries. Allow max voltage of 55.2 V again, if SoC is

; once below 80%

; Linear mode:

; The battery reached max voltage of 55.2 V and the max cell difference is 0.010 V, then switch to float

; voltage of 53.6 V after 900 additional seconds to don't stress the batteries. Allow max voltage of

; 55.2 V again if max cell difference is above 0.080 V or SoC below 80%.

; Charge voltage control management enable (True/False).

CVCM_ENABLE = True

; -- CVL reset based on cell voltage diff (linear mode)

; Specify cell voltage diff where CVL limit is kept until diff is equal or lower

CELL_VOLTAGE_DIFF_KEEP_MAX_VOLTAGE_UNTIL = 0.010

; Specify cell voltage diff where MAX_VOLTAGE_TIME_SEC restarts if diff is bigger

CELL_VOLTAGE_DIFF_KEEP_MAX_VOLTAGE_TIME_RESTART = 0.013

; Specify cell voltage diff where CVL limit is reset to max voltage, if value get above

; the cells are considered as imbalanced, if the cell diff exceeds 5% of the nominal cell voltage

; e.g. 3.2 V * 5 / 100 = 0.160 V

CELL_VOLTAGE_DIFF_TO_RESET_VOLTAGE_LIMIT = 0.080

; -- CVL reset based on SoC option (step mode & linear mode)

; Specify how long the max voltage should be kept

; Step mode: If reached then switch to float voltage

; Linear mode: If cells are balanced keep max voltage for further MAX_VOLTAGE_TIME_SEC seconds

MAX_VOLTAGE_TIME_SEC = 900

; Specify SoC where CVL limit is reset to max voltage

; Step mode: If SoC gets below

; Linear mode: If cells are unbalanced or if SoC gets below

SOC_LEVEL_TO_RESET_VOLTAGE_LIMIT = 80

; --------- Cell Voltage Current limitation (affecting CCL/DCL) ---------

; Description: Maximal charge / discharge current will be in-/decreased depending on min and max cell voltages

; Example:

; 18 cells * 3.55 V/cell = 63.9 V max charge voltage

; 18 cells * 2.70 V/cell = 48.6 V min discharge voltage

; But in reality not all cells reach the same voltage at the same time. The (dis)charge current

; will be (in-/)decreased, if even ONE SINGLE BATTERY CELL reaches the limits

; Charge current control management referring to cell-voltage enable (True/False).

CCCM_CV_ENABLE = True

; Discharge current control management referring to cell-voltage enable (True/False).

DCCM_CV_ENABLE = True

; Set steps to reduce battery current

; The current will be changed linear between those steps if LINEAR_LIMITATION_ENABLE is set to True

CELL_VOLTAGES_WHILE_CHARGING = 3.55, 3.50, 3.45, 3.30

MAX_CHARGE_CURRENT_CV_FRACTION = 0, 0.05, 0.7, 1

CELL_VOLTAGES_WHILE_DISCHARGING = 2.70, 2.80, 2.90, 3.10

MAX_DISCHARGE_CURRENT_CV_FRACTION = 0, 0.1, 0.5, 1

; --------- Cell Voltage limitation (affecting CVL) ---------

; This function prevents a bad balanced battery to overcharge the cell with the highest voltage and the bms to

; switch off because of overvoltage of this cell.

;

; Example:

; 15 cells are at 3.4v, 1 cell is at 3.6v. Total voltage of battery is 54.6v and the Victron System sees no reason to

; lower the charging current as the control_voltage (Absorption Voltage) is 55.2v

; In this case the Cell Voltage limitation kicks in and lowers the control_voltage to keep it close to the MAX_CELL_VOLTAGE.

;

; In theory this can also be done with CCL, but doing it with CVL has 2 advantages:

; - In a well balanced system the current can be kept quite high till the end of charge by using MAX_CELL_VOLTAGE for charging.

; - In systems with MPPTs and DC-feed-in activated the Victron systems do not respect CCL, so CVL is the only way to prevent the

; highest cell in a bad balanced system from overcharging.

;

; There are 2 methods implemented to calculate CVL:

; 1. penalty_sum-Method (CVL_ICONTROLLER_MODE = False)

; The voltage-overshoot of all cells that exceed MAX_CELL_VOLTAGE is summed up and the control voltage is lowered by this "penalty_sum".

; This is calculated every LINEAR_RECALCULATION_EVERY seconds.

; In fact, this is a P-Controller.

; 2. I-Controller (CVL_ICONTROLLER_MODE = True)

; An I-Controller tries to control the voltage of the highest cell to MAX_CELL_VOLTAGE + CELL_VOLTAGE_DIFF_KEEP_MAX_VOLTAGE_UNTIL.

; (for example 3.45 V + 0.01 V = 3.46 V). If the voltage of the highest cell is above this level, CVL is reduced. If the voltage is below, CVL is

; increased until cellcount*MAX_CELL_VOLTAGE.

; An I-Part of 0.2 V/Vs (CVL_ICONTROLLER_FACTOR) has proved to be a stable and fast controlling-behaviour.

; This method is not as fast as the penalty_sum-Method but usually smoother and more stable against toggling and has no stationary deviation.

; More info: https://github.com/Louisvdw/dbus-serialbattery/pull/882

CVL_ICONTROLLER_MODE = False

CVL_ICONTROLLER_FACTOR = 0.2

; --------- Temperature limitation (affecting CCL/DCL) ---------

; Description:

; Maximal charge / discharge current will be in-/decreased depending on temperatures

; NOTE: The temperatures are in ° Celsius. Temperature sensor 1 to 4 are used for the calculation.

; Example:

; The temperature limit will be monitored to control the currents. If there are two temperature sensors,

; then the worst case will be calculated and the more secure lower current will be set.

; Charge current control management referring to temperature enable (True/False).

CCCM_T_ENABLE = True

; Discharge current control management referring to temperature enable (True/False).

DCCM_T_ENABLE = True

; Set steps to reduce battery current

; The current will be changed linear between those steps if LINEAR_LIMITATION_ENABLE is set to True

TEMPERATURES_WHILE_CHARGING = 0, 2, 5, 10, 15, 20, 35, 40, 55

MAX_CHARGE_CURRENT_T_FRACTION = 0.00, 0.10, 0.20, 0.40, 0.80, 1.00, 1.00, 0.40, 0.00

TEMPERATURES_WHILE_DISCHARGING = -20, 0, 5, 10, 15, 45, 55

MAX_DISCHARGE_CURRENT_T_FRACTION = 0.00, 0.20, 0.30, 0.40, 1.00, 1.00, 0.00

; --------- SOC limitation (affecting CCL/DCL) ---------

; Description:

; Maximal charge / discharge current will be increased / decreased depending on State of Charge

; Since the SoC is not as accurate as the cell voltage, this option is disabled by default

; Example:

; The SoC limit will be monitored to control the currents.

; Charge current control management referring to SoC enable (True/False).

CCCM_SOC_ENABLE = False

; Discharge current control management referring to SoC enable (True/False).

DCCM_SOC_ENABLE = False

; Set steps to reduce battery current

; The current will be changed linear between those steps if LINEAR_LIMITATION_ENABLE is set to True

SOC_WHILE_CHARGING = 98, 95, 90, 85

MAX_CHARGE_CURRENT_SOC_FRACTION = 0.10, 0.20, 0.50, 1.00

SOC_WHILE_DISCHARGING = 5, 10, 15, 20

MAX_DISCHARGE_CURRENT_SOC_FRACTION = 0.10, 0.20, 0.50, 1.00

; --------- Time-To-Go ---------

; Description:

; Calculates the time to go shown in the GUI

; Recalculation is done based on TIME_TO_SOC_RECALCULATE_EVERY

TIME_TO_GO_ENABLE = True

; --------- Time-To-Soc ---------

; Description:

; Calculates the time to a specific SoC

; Example:

; TIME_TO_SOC_POINTS = 50, 25, 15, 0

; 6h 24m remaining until 50% SoC

; 17h 36m remaining until 25% SoC

; 22h 5m remaining until 15% SoC

; 28h 48m remaining until 0% SoC

; Set of SoC percentages to report on dbus and MQTT. The more you specify the more it will impact system performance.

; [Valid values 0-100, comma separated list. More that 20 intervals are not recommended]

; Example: TIME_TO_SOC_POINTS = 100, 95, 90, 85, 75, 50, 25, 20, 10, 0

; Leave empty to disable

TIME_TO_SOC_POINTS =

; Specify TimeToSoc value type [Valid values 1, 2, 3]

; 1 Seconds

; 2 Time string <days>d <hours>h <minutes>m <seconds>s

; 3 Both seconds and time string "<seconds> [<days>d <hours>h <minutes>m <seconds>s]"

TIME_TO_SOC_VALUE_TYPE = 1

; Specify in seconds how often the TimeToSoc should be recalculated

; Minimum are 5 seconds to prevent CPU overload

TIME_TO_SOC_RECALCULATE_EVERY = 60

; Include TimeToSoC points when moving away from the SoC point [Valid values True, False]

; These will be as negative time. Disabling this improves performance slightly

TIME_TO_SOC_INC_FROM = False

; --------- Additional settings ---------

; Specify one or more BMS types to load else leave empty to try to load all available

; Available BMS:

; Daly, Ecs, EG4_Lifepower, EG4_LL, HeltecModbus, HLPdataBMS4S, Jkbms, Jkbms_pb, LltJbd, Renogy, Seplos

; Available BMS, but disabled by default (just enter one or more below and it will be enabled):

; ANT, MNB, Sinowealth

BMS_TYPE =

; Exclude this serial devices from the driver startup

; Example:

; /dev/ttyUSB2, /dev/ttyUSB4

EXCLUDED_DEVICES =

; BMS poll interval in seconds

; If the driver consumes to much CPU, you can increase this value to reduce refresh rate

; and CPU usage

; Default for most BMS is 1 second, some BMS may have a higher value

; Leave empty to use the BMS default value, decimal values are allowed

POLL_INTERVAL =

; Auto reset SoC

; If on, then SoC is reset to 100%, if the value switches from absorption to float voltage

; Currently only working for Daly BMS and JKBMS BLE

AUTO_RESET_SOC = True

; Publish the config settings to the dbus path "/Info/Config/"

PUBLISH_CONFIG_VALUES = False

; Select the format of cell data presented on dbus [Valid values 0,1,2,3]

; 0 Do not publish all the cells (only the min/max cell data as used by the default GX)

; 1 Format: /Voltages/Cell (also available for display on Remote Console)

; 2 Format: /Cell/#/Volts

; 3 Both formats 1 and 2

BATTERY_CELL_DATA_FORMAT = 1

; Simulate Midpoint graph (True/False).

MIDPOINT_ENABLE = False

; Battery temperature

; Specify how the battery temperature is assembled

; 0 Get mean of temperature sensor 1 to sensor 4

; 1 Get only temperature from temperature sensor 1

; 2 Get only temperature from temperature sensor 2

; 3 Get only temperature from temperature sensor 3

; 4 Get only temperature from temperature sensor 4

TEMP_BATTERY = 0

; Temperature sensor 1 name

TEMP_1_NAME = Temp 1

; Temperature sensor 2 name

TEMP_2_NAME = Temp 2

; Temperature sensor 2 name

TEMP_3_NAME = Temp 3

; Temperature sensor 2 name

TEMP_4_NAME = Temp 4

; Show additional info in GUI -> Serialbattery -> Parameters

; This will show additional information to better understand how the driver works

; and what values are currently set which are not shown elsewhere in the GUI

; You have to scroll down to see the additional information

GUI_PARAMETERS_SHOW_ADDITIONAL_INFO = False

; --------- BMS specific settings ---------

; -- Unique ID settings

; Some already assembled BMS have no unique ID and no possibility to set one. In this case

; you can use the USB port as the unique ID.

; It may be possible that VRM ID's and custom names are not saved/restored correctly in this case.

USE_PORT_AS_UNIQUE_ID = False

; -- LltJbd settings

; SoC low levels

; Note:

; SOC_LOW_WARNING is also used to calculate the Time-To-Go even if you are not using a LltJbd BMS

SOC_LOW_WARNING = 20

SOC_LOW_ALARM = 10

; -- Daly settings

; Battery capacity (amps), if the BMS does not support reading it

BATTERY_CAPACITY = 50

; Invert Battery Current. Default non-inverted. Set to -1 to invert

INVERT_CURRENT_MEASUREMENT = 1

; -- JKBMS settings

; Predefines cell count for Jkbms_can

; The cell count should be auto-detected by identifying the highest cell number,

; but this process may be sometimes slow what could cause that cells voltage is not not

; updated in VenusOS. Try this workaround if you experience problems with cell voltage.

JKBMS_CAN_CELL_COUNT = 1

; -- ESC GreenMeter and Lipro device settings

GREENMETER_ADDRESS = 1

LIPRO_START_ADDRESS = 2

LIPRO_END_ADDRESS = 4

LIPRO_CELL_COUNT = 15

; -- HeltecModbus (Heltec SmartBMS/YYBMS) settings

; Set the Modbus addresses from the adapters

; Separate each address to check by a comma like: 1, 2, 3, ...

; factory default address will be 1

HELTEC_MODBUS_ADDR = 1

; -- Seplos V3 settings

; Use min/max cell voltage, CVL, CCL and DCL from the BMS

SEPLOS_USE_BMS_VALUES = False

; --------- Voltage drop ---------

; If you have a voltage drop between the BMS and the charger because of wire size or length

; then you can specify the voltage drop here. The driver will then add the voltage drop

; to the calculated CVL to compensate.

; Example:

; cell count: 16

; MAX_CELL_VOLTAGE = 3.45

; max voltage calculated = 16 * 3.45 = 55.20

; CVL is set to 55.20 V and the battery is now charged until the charger reaches 55.20 V.

; The BMS now measures 55.05 V since there is a voltage drop of 0.15 V on the cable.

; Since the dbus-serialbattery reads the voltage of 55.05 V from the BMS the max voltage

; of 55.20 V is never reached and max voltage is kept forever.

; By setting the VOLTAGE_DROP to 0.15 V the voltage on the charger is increased and the

; target voltage on the BMS is reached.

VOLTAGE_DROP = 0.00